Design for Automated Sorting Solutions

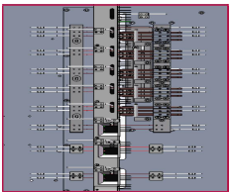

The G-300 Gravity Sorting Machine is a fully automated system meticulously crafted for testing TO series packaged power devices.

It seamlessly integrates multiple testing stations in series, encompassing insulation testing, conventional electrical performance testing, laser marking, brush dust removal, and visual inspection within a singular, efficient device.

Key Features

- Optimal 8000-10000pcs UPH

- 2 Insulation + 4 Electrical Performance Testing Position

- 15 Stage Automatic Tube Collection

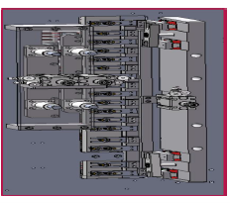

The testing station is equipped with a quantity that can simultaneously accommodate the polarity testing

requirements of multiple product models.

Unique material testing positioning switching mechanism, improving efficiency and facilitating maintenance.

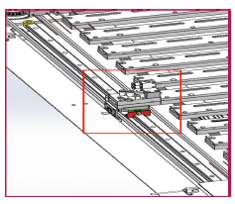

The sorting shuttle's material-blocking air cylinder adopts a bottom-inlet air method, making the mechanism lightweight and enhancing operational performance.